It’s official- the stream-side channel experiment is over!

After two weeks of sampling, our team completed both rounds of metabolism,

nutrient uptake and nitrogen fixation measurements. These efforts involved 15

people, 300 chamber incubations, and scrubbing biofilm off more than 1,000

tiles. Although it’s a relief to be done with the long days, I’m a bit sad

to see the channel experiment come to an end. What am I supposed to do with

myself now that I don’t have any biofilm to grow or channels to maintain? I

guess I’ll have to take up a hobby (gardening should be similar to growing

biofilm...), and of course analyzing all that data will keep me busy for a

while!

Anyways, here are some highlights from the sampling events:

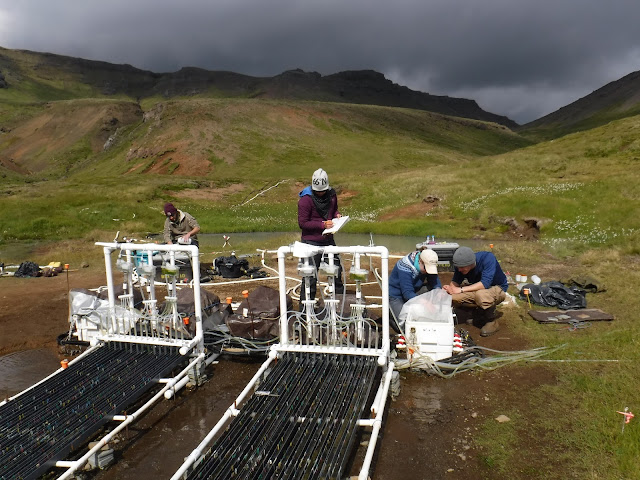

Day 1: A flawless team measuring metabolism on a flawless day

Day 2: Weather not so flawless, but our crew stayed strong to complete nitrogen and phosphorus uptake measurements

Days 3 and 4: N-fixation Nation!

Annette is a MIMs Buddha

This is what learning looks like

The final sampling push

At the channels, the optimal observer-to-worker ratio is 3:1

...except for the last day of sampling, when everyone just takes a nap